Liquid Silicone Rubber Injection Molding Medical Grade Silicone Overmolding

- group name

- Medical Grade Silicone Overmolding

- Min Order

- 1 piece

- brand name

- SiliconePlus | Silicone OverMolding Manufacturing

- model

- 13-lyasilicone20240915

- Nearest port for product export

- Yantian (shenzhen,guangdong, china), Shekou (shenzhen,guangdong, china)

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash, Escrow

- update time

- Fri, 27 Feb 2026 22:25:23 GMT

Paramtents

Material silicone+metal

color Customizable according to your needs

Technology Silicone overmolding process

Product size Customized to your needs

Is it spot No, these are custom made products.

Is it a factory We are the source factory for customized silicone

Product Application Industry New energy vehicle industry

Packging & Delivery

-

Min Order1 piece

Briefing

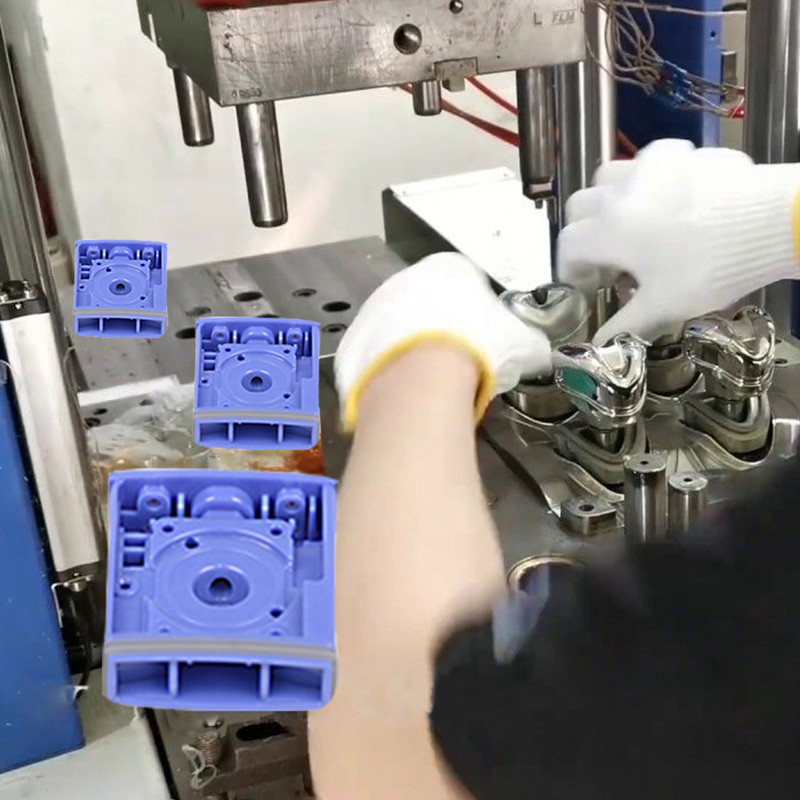

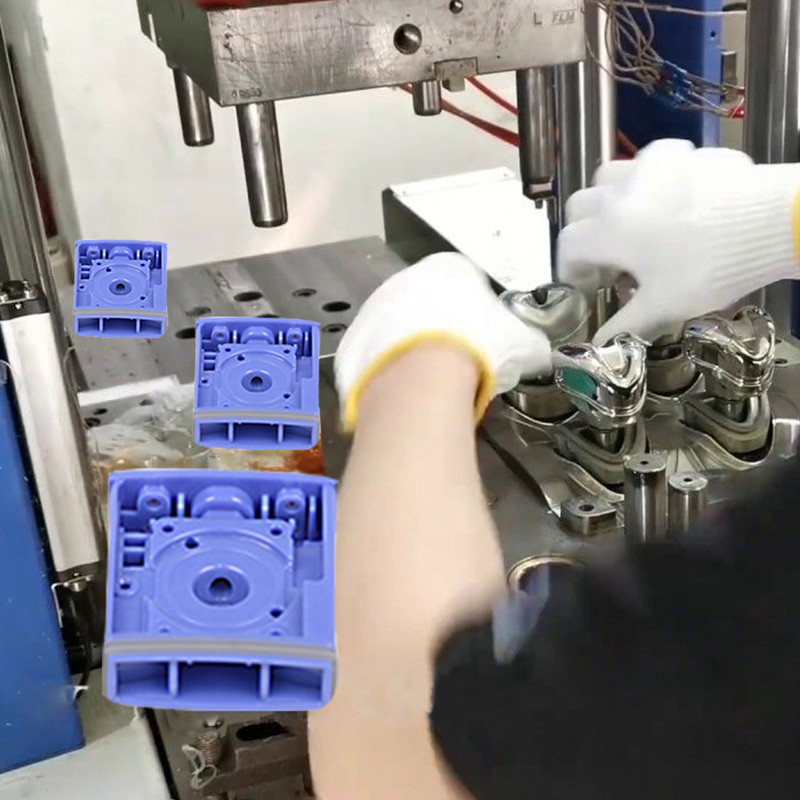

Liquid Silicone Rubber Injection Molding is an advanced manufacturing process that is particularly suitable for the medical industry. Medical Grade Silicone Overmolding technology enables precision manufacturing of medical devices, ensuring their high safety and reliability during use. The combination of these two processes not only improves the durability of the product, but also meets strict medical standards, making medical grade silicone products have better biocompatibility and performance, making them an ideal choice for medical device manufacturing.

Detailed

Silicone and Metal Overmolding Solutions in Medical Grade Silicone Overmolding

Liquid Silicone Rubber Injection Molding

Product Introduction: This product is manufactured using Liquid Silicone Rubber Injection Molding technology and is designed specifically for the medical industry. Through our advanced injection molding technology, this product has excellent biocompatibility, high durability, and strict compliance with medical-grade standards. This product is designed to meet the high requirements of medical equipment for safety, precision, and durability, and is widely used in various medical devices and health care equipment.

Product Features:

Medical Grade Silicone: Using Medical Grade Silicone to ensure the safety and reliability of the product in medical applications, fully complying with international medical certification standards such as FDA and ISO.

Precision Molding: Through the precise Liquid Silicone Rubber Injection Molding process, the product is ensured to have excellent dimensional accuracy and consistency, suitable for high-demand medical scenarios.

Biocompatibility: This product has been rigorously tested and has excellent biocompatibility. It can be in long-term contact with human tissue, safe and non-toxic.

High Temperature Stability and Chemical Resistance: Withstands high temperature disinfection and chemical reagent erosion in medical environments to ensure the stable performance of the product in various medical operations.

Soft and High Strength: The product has both soft touch and strong physical strength. It has high elasticity and durability during use and is suitable for sealing, protection and coating of a variety of medical devices.

Application scenarios of silicone + Metal process

FAQs about Silicone + Metal in the Medical Industry

Q1: What is Liquid Silicone Rubber Injection Molding?

Liquid Silicone Rubber Injection Molding is a manufacturing process for producing high-precision silicone products. This technology injects liquid silicone into the mold and quickly solidifies it at high temperature. It is suitable for the production of medical-grade products that require high precision and stable quality.

Q2: What is Medical Grade Silicone Overmolding?

Medical Grade Silicone Overmolding is a process that coats medical grade silicone onto the surface of other materials (such as plastics and metals) to enhance the durability, biocompatibility and functionality of the product. It is widely used in medical devices, especially in products that require a combination of multiple materials.

Q3:What certification standards do your medical silicone products meet?

Our medical silicone products meet multiple international standards, including FDA and ISO 13485 certification, ensuring their safety, reliability and high quality in medical applications.

- If the above products are not suitable for your workpiece, please tell us your needs and we will provide you with the most satisfactory drawings.

- contact us