Precision Silicone Overmolding for Data Cables - High-Quality Processing Solutions by Siliconeplus

- group name

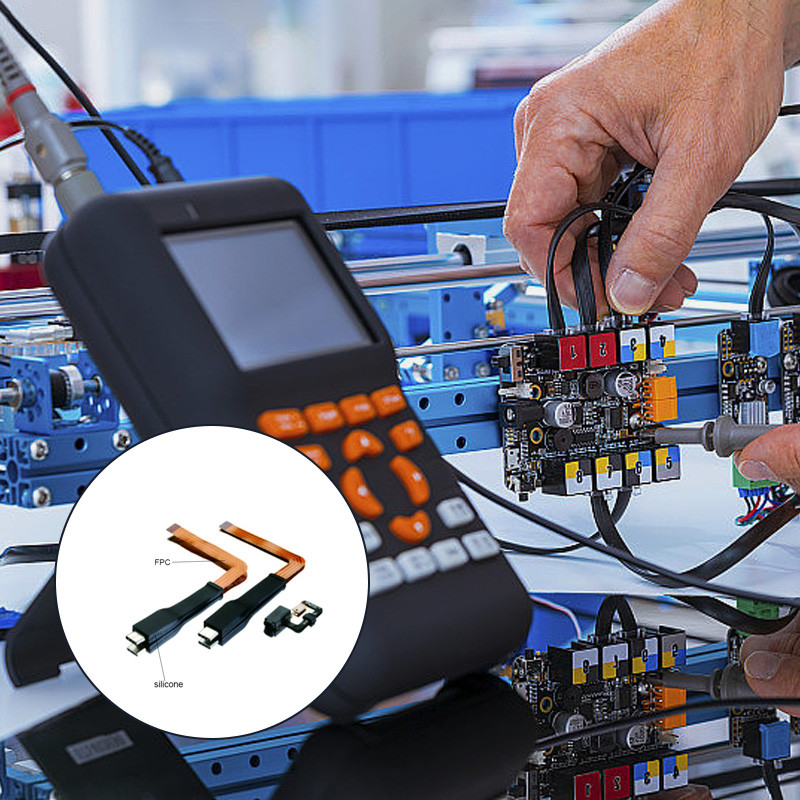

- 3C Electronics Silicone Overmolding

- Min Order

- 1 piece

- brand name

- SiliconePlus | Silicone OverMolding Manufacturing

- model

- 32-lyasilicone20241128

- Nearest port for product export

- Yantian (shenzhen,guangdong, china), Shekou (shenzhen,guangdong, china)

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash, Escrow

- update time

- Fri, 06 Mar 2026 21:10:32 GMT

Paramtents

ISO 13485 Certified Meets international standards for medical device

Customizable Options for color and design to meet specific need

Medical-Grade Silicone Hypoallergenic, biocompatible, and safe for prolon

Packging & Delivery

-

Min Order1 piece

Briefing

OEM & ODM Precision Silicone Overmolding for Data Cables - Durable, custom solutions by Siliconeplus.

Detailed

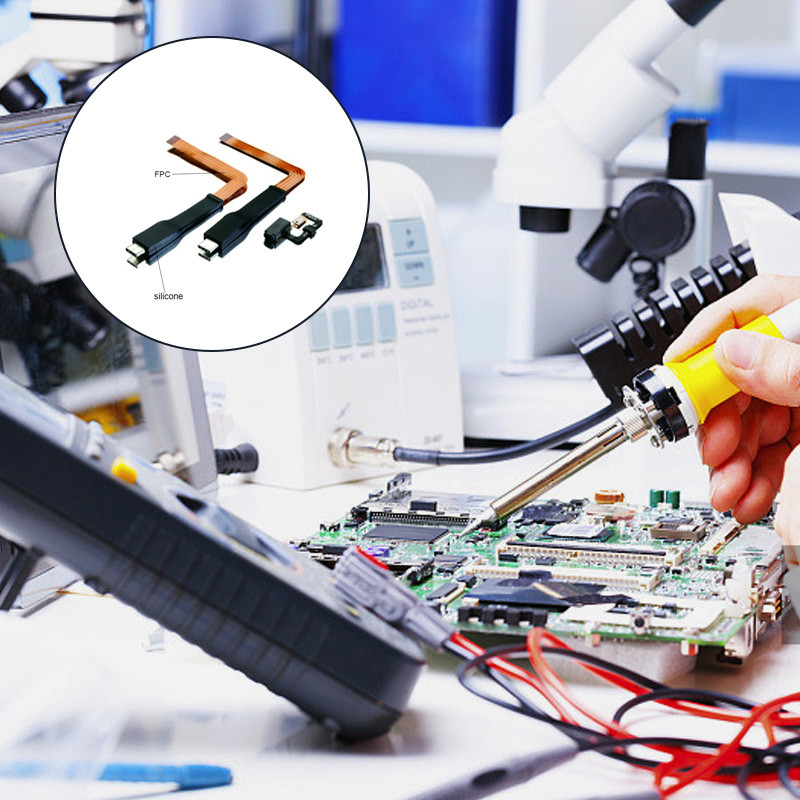

What is silicone overmolding, and how does it benefit data cables?

Silicone overmolding is a high-precision manufacturing process where liquid silicone rubber (LSR) is molded directly onto data cable components. This process enhances the cables by providing superior insulation, waterproofing, and durability. Silicone’s flexibility and resistance to extreme temperatures and environmental factors make it ideal for protecting delicate cable assemblies in demanding conditions.

we specialize in providing customized overmolding solutions tailored to your specific requirements. Whether it’s unique cable dimensions, specialized connectors, or performance standards, our engineering team designs molds and processes to deliver precisely what you need. Customization options include material properties, colors, shapes, and additional features like logo embossing

What are the key properties of silicone used in overmolding?

The silicone used in our overmolding processes offers several important properties:

Heat Resistance: Performs well in temperatures ranging from -60°C to 250°C.

Flexibility: Maintains elasticity even after repeated bending.

Waterproofing: Provides a complete seal against moisture and liquids.

Aging Resistance: Ensures longevity by resisting UV exposure and chemical

Biocompatibility: Safe for use in medical and food-grade applications.

These properties make silicone a superior choice for protecting cable assemblies.

Customer Cases

Environmental Resistance: The cables would be exposed to high temperatures (up to 200°C), vibrations, and oil in engine compartments.

Precision Requirements: The overmolding needed to fit intricate connectors precisely to prevent signal interference and ensure a snug fit.

Volume and Speed: The client required a high production volume of over 100,000 units per month with a tight delivery schedule.

Certifications: The finished product had to meet automotive industry standards, including RoHS and ISO/TS 16949 compliance.

Our Solution

1.Material Selection: Our engineering team selected high-performance liquid silicone rubber (LSR) for its excellent thermal stability, flexibility, and oil resistance.

2.Custom Mold Design: Using our in-house mold-making department, we designed precision molds to accommodate the unique connector geometry. The molds ensured a tight, secure fit around the cables while allowing for smooth demolding.

3.Overmolding Process: Leveraging advanced silicone overmolding techniques, we encapsulated the data cables with uniform silicone layers,

enhancing durability and providing complete protection against oil, water, and heat.

4.Quality Control: We implemented strict quality checks, including high-temperature testing, tensile strength assessment, and fit validation for connectors, ensuring each unit met the client's exacting standards.

5.Scalable Production: With 20 production lines and optimized workflows, we ramped up production to meet the client's volume requirements while adhering to the delivery schedule.

Results:

Enhanced Product Durability: The silicone overmolded cables exceeded performance expectations, withstanding extreme temperatures, vibrations, and environmental exposure without degradation.

Precision Fit: The custom molds ensured perfect alignment with the connectors, enabling seamless integration into the client’s EV systems.

Compliance Achieved: The final product met all required certifications, including RoHS and ISO standards, enabling the client to proceed with global distribution.

On-Time Delivery: We successfully delivered over 100,000 units monthly, helping the client meet their production goals without delays.

Improved Customer Satisfaction: The client praised our technical expertise, responsiveness, and ability to deliver high-quality solutions under tight deadlines.

Customer Feedback

"Siliconeplus exceeded our expectations with their precision silicone overmolding services. Their technical expertise and commitment to quality ensured that our cables met the rigorous demands of the automotive industry. We look forward to working with them on future projects."

— Procurement Manager, Leading EV Manufacturer

This real-world example showcases Siliconeplus's ability to provide tailored solutions that address complex challenges, emphasizing your expertise in precision silicone overmolding.

Frequently Asked Questions (FAQs)

What industries are these silicone overmolded cables suitable for?

Our silicone overmolded cables are commonly used in industries such as:

.Automotive: for wiring harnesses and connectors exposed to heat and vibration.

.Medical: for biocompatible cables in diagnostic and surgical devices.

.Consumer Electronics: for durable charging and data transfer cables.

.Industrial Equipment: for cables in harsh manufacturing environments.

Their reliability and durability make them suitable for any high-performance application.

What are the key properties of silicone used in overmolding?

The silicone used in our overmolding processes offers several important properties:

Heat Resistance: Performs well in temperatures ranging from -60°C to 250°C.

Flexibility: Maintains elasticity even after repeated bending.

Waterproofing: Provides a complete seal against moisture and liquids.

Aging Resistance: Ensures longevity by resisting UV exposure and chemical degradation.

Biocompatibility: Safe for use in medical and food-grade applications.

These properties make silicone a superior choice for protecting cable assemblies.

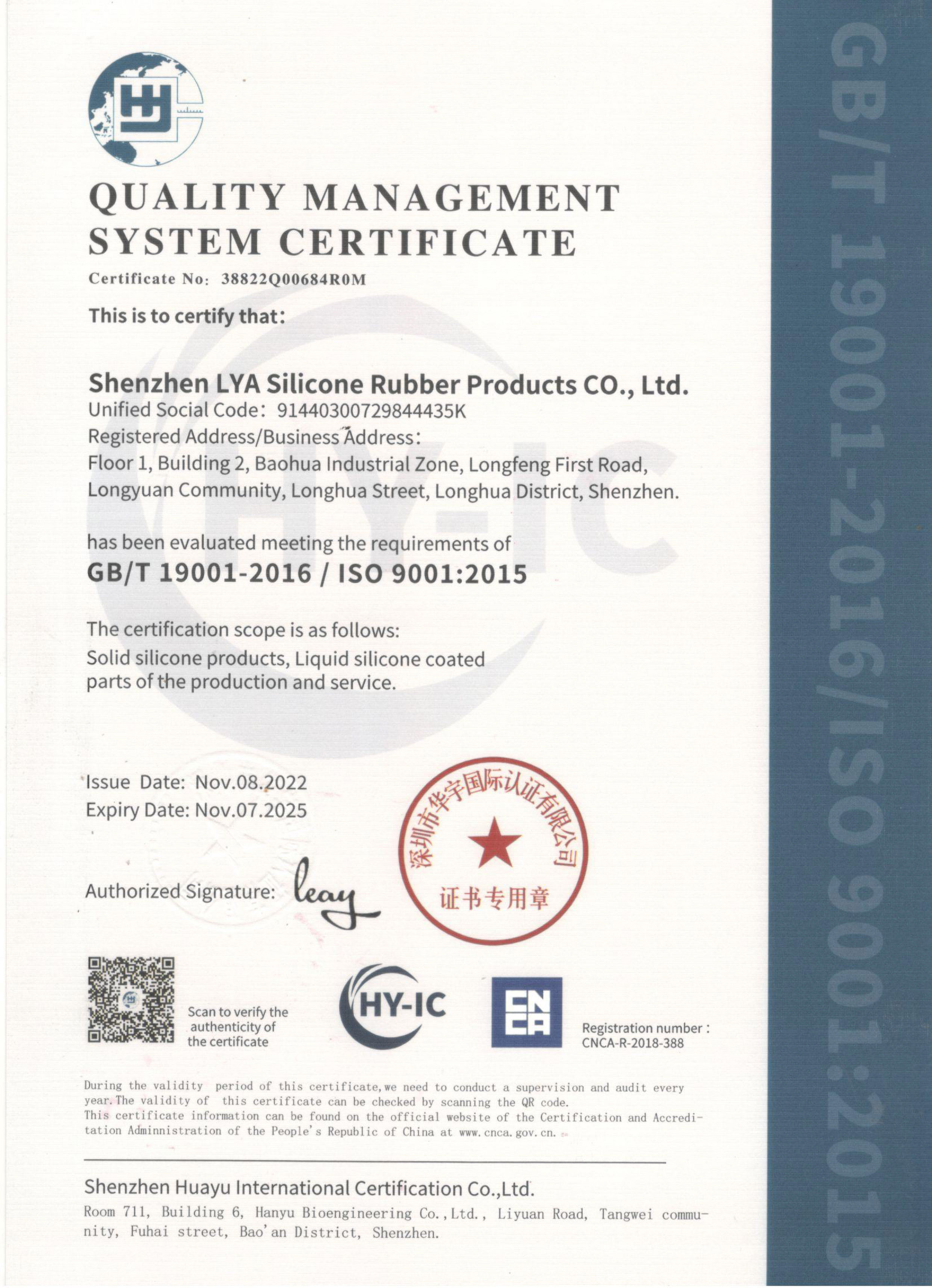

Do you provide certifications for your silicone overmolded products?

Yes, all our silicone overmolded products comply with industry standards and regulations. We provide certifications such as RoHS, REACH, and ISO 9001 to guarantee that our products meet safety, environmental, and quality requirements. Additional documentation can be provided upon request.